Nowadays the production line in industries is really competitive; factory automation is very crucial in order to enhance productivity, decrease expenses, and deliver quality finished products. Pneumatic cylinders are important elements in factory automation systems since they provide reliable power stroke and motion control. This paper aims at discussing why pneumatic cylinders are crucial in factory automation, and pros about using pneumatic cylinders for industrial automation suppliers and manufacturers.

Pneumatic Cylinder and Automation

Pneumatic cylinders are elements providing linear or rotary motion for a mechanical system powered by compressed air. They find frequent usage in factory automation mainly in material handling, packaging, assembling and other related functions. Because of their basic construction that does not contain wheels they are very economical, cheap, and long-lasting, which makes them the choice of many industries.

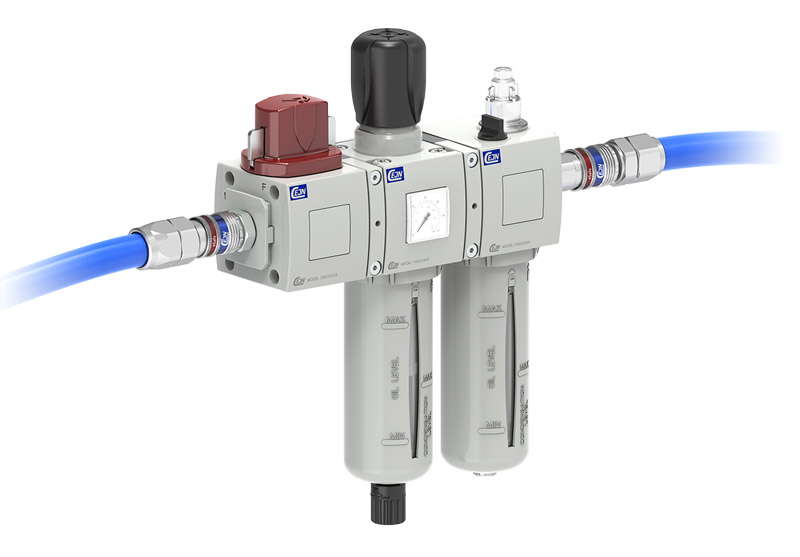

A minimum frl unit in a pneumatic system is desired to work effectively on pneumatic cylinders since it filters and controls the air readily available. Integration of an FRL assembly to the pneumatic cylinders filter, regulator, and lubricators improves the performance and life cycle of the cylinders in the factory automation systems.

Pneumatic cylinders are one of the basics of many manufacturing facilities since they offer the physical push in moving, lifting, or aligning an object in the right place. Each of them is characterized by great multifunctionality and the ability to perform various activities that help to increase factory productivity.

Advantages of Pneumatic Cylinders for Factories

That is why pneumatic cylinders have numerous benefits that are crucial for the factory’s automation. For that reason, they come in cheaper than other motion control technologies such as hydraulic or electrical actuators. Air is the main source of energy used in pneumatic cylinders, and this is easily produced and is cheap in expenses.

Thirdly, pneumatic cylinders are small in sizes and lightweight and consequently can be easily fitted on any system. The basic design also minimizes wear, and tear and as such, factories using these types of bearings have minimal time off for repairs. This makes them quite suitable for suppliers in industrial automation who are keen on offering their clientele quality and efficiency in the parts supplied.

Another strength is their ability to work under conditions of high temperature or elevated level of dust and moisture. This durability guarantees that factories can continue their operations and can work for long hours, sometimes making it difficult for them to break down due to harsh conditions, thus making pneumatic cylinders in demand for automation.

How Pneumatic Cylinders Improve Efficiency

Pneumatic cylinders are intended for speed control and accuracy to meet factory’s challenges of repetitive tasks. This is especially true in automotive, food processing and electronics industries where there is high demand for products and thus high speed production is highly expected.

Implementation of pneumatic cylinders thereby reduces human intervention hence elimination of rig, mistakes and repetitive work. Using methods such as advanced pneumatic systems and FRL units factories can guarantee absolutely stable working pressure and flux, which are providing favorable conditions for streamlines production lines.

In addition, pneumatic cylinders boast of versatility in that they can be designed to fit into a particular process on top of the fact that businesses can adapt them to meet their specific needs. That is also why using pneumatic cylinders is useful when it comes to small and delicate tasks as well as when executing large and complex operations – the versatility that is crucial for production lines.

Key Applications of Pneumatic Cylinders

Pneumatic cylinders are used throughout processes in a multitude of industries and their use can be counted in the thousands for a variety of applications making them a flexible aspect of factory automation. Some common applications include:

– Material Handling: Pneumatic cylinders are applied for the transportation of materials, loading and positioning in production lines to minimize the impact on the final product and maximize production flow.

– Packaging: In the packaging industry particularly, the applications of pneumatic cylinders are for sealing and filling as well as labeling; factories are thus in a position to work at higher speeds.

– Assembly Lines: Pneumatic cylinders assist in the provision of accurate positioning of parts that need to be assembled reducing error margin.

– Robotic Systems: A good example is the use of robotic arms and automated machines where many of them use pneumatic cylinders as the actuating mechanism because it will be cost effective and efficient when used for complex motion.

Distributors of industrial automation products, especially pneumatic cylinders, gain tremendously since these products fit almost all sectors.

Maintenance and Reliability of Pneumatic Systems

Keeping optimal and constant pneumatic cylinders is extremely important for the factory automation system. Maintenance carries the implication that cylinders are properly run to improve the operating time and decrease chances of repair costs. Of the factors that must be monitored frequently, perhaps the most critical is the state of the FRL unit mounted in the pneumatic system. In this way, the FRL unit strains undesirable particles, controls pressure and feeds the required amount of oil to the cylinder , reducing wear and tear of the cylinders.

Other measures which can also improve the life expectancy in y of cylinders include regular inspection, cleaning and lubricating of the cylinders. Organizations should also incorporate quality components from reputable industrial automation suppliers in order to have long dispatching of the equipment and its efficiency. Having a distributor alliance gives access to right quality pneumatic systems and advice on how to maximize automation.

At the core of factory automation, pneumatic cylinders provide many benefits including affordability, sturdiness and numerous applicability. They have a very important function in enhancing production standards, keeping down the amount of hand work, and maintaining standardization of production. When incorporated into automation systems, pneumatic cylinders are a critical means to increase performance as well as reliability.

Industrial automation distributors can go further to ensure that factories increase their efficiency by supplying them with high quality pneumatic cylinders and FRL units and other related accessories. Obviously most factories today face stiff competition, however, with proper maintenance and careful selection of components, factories can realize the full potential of pneumatic cylinders.